Complete Packaging Line For Flammable Chemical Product Into Stand-Up Pouches With Liquid Dispenser Fitment

Market leader of Household products wanted an innovative packaging solution for flammable chemical product filling into a pre-made stand-up pouch with liquid dispenser fitment.

The customer was looking for a reliable and high-performance solution to automatize their line of pouches and products.

When the company approached FLtècnics we were sure to comply all their requirements by offering our versatile Horizontal Fill & Seal machine model FL 3.3 SV PMP STU2 duplex.

CUSTOMER CHALLENGE

Our customer wanted an automatic system that, starting from already made pouches of different sizes, could place the base of the valve, dose through the valve and place the dispenser at a production speed of 3.600 pouches / hour.

For this reason, FLTècnics has been involved in the development of the right solution to satisfy all the customer’s requirement in terms of supplying a fully automatic system as per customer’s URS

THE FLTÈCNICS SOLUTION

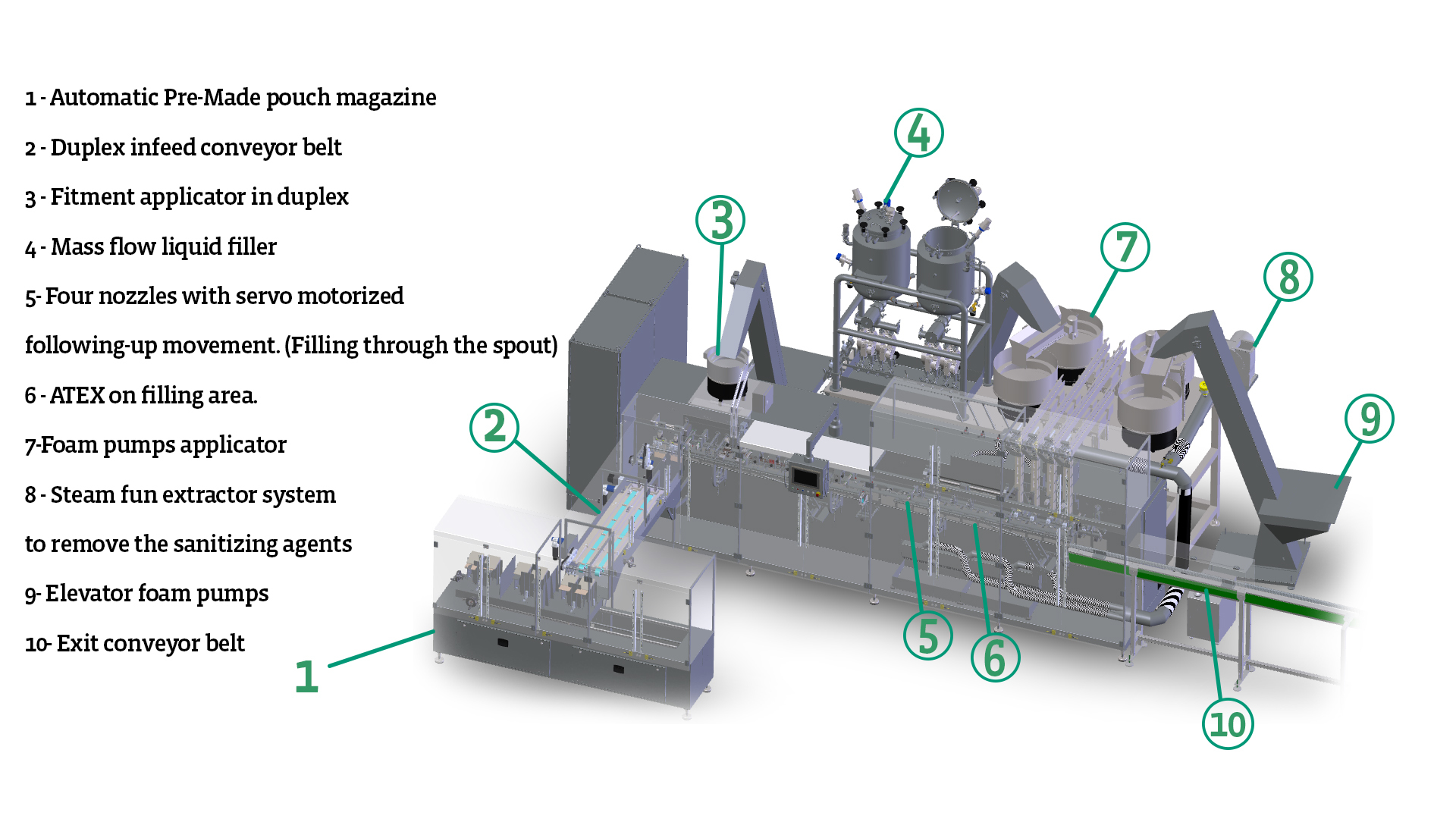

FLtècnics has supplied a complete solution for a HFS pre-made machine model FL 3.3 SV PMP STU2 in duplex version as per customer’s URS for packing different type of chemical products into pre-made stand-up pouch and dispenser fitment with production up to 3.600 pouches/per hour

The fitment system for the base and dispenser applicator and product filling system through the spout, was the key solution for this project as it offers specific features.

- Speed: up to 60 pouches/ per minute.

- Sachet style: Stand up & gusseted pouch

- ATEX configuration of filling area

- Filling system: Mass Flow meter from Endress & Hausser

RESULTS

- High accuracy dosing < 1%

- Customized & Viable solution

- Easy to clean

- Efficiency

- Product’s safety

- Sealing integrity for product’s safety

- Finished sachet with free leakage.

CHARACTERISTICS OF THIS EQUIPMENT

- PLC and HMI with interactive touch screen

- Machine frame made in stainless steel AISI 304.

- Sanitary design in compliance with chemical & Pharma requirements and in compliance with FDA

- Central lubrication system.

- All parts in contact with the product made in stainless steel AISI-316L.

- Fully automatic pre-made pouch infeed conveyor belt

- Servo-motorized pick-up pouch transfer system with pouch positioning grippers

- Duplex base applicator system

- Top suction cups

- Four (4) independent top sealing jaws & two (2) independent top cooling plates

- Fittings Checking station

- Vacuum station to remove air of pouches before filling

- Mass Flow meter for product filling with high accuracy and Volume adjustment in real time (including CIP system)

- Four (4) nozzles with lateral movement and filling through the spout technology

- Steam fun extractor system to remove the sanitizing agents for operator’s protection

- Foam pump dispenser of 4 heads

- Exit conveyor belt

- UL 508 A certification on the electrical cabinet

- ANSI B11.0 USA regulation

- HAZLOC validation (Hazardous location) to produce flammable products.

- ATEX on filling area for flammable products