Complete Packaging Line For 2.3 Kg of Pineapple Tidbits in Syrup in 4-Side Seal Sachets

One of the leading international fruit companies needed a comprehensive packaging solution for their production plant in the Philippines. They decided to open up a tender and invited proposals from leading manufacturers to find the best way to efficiently package 2.3 kg of pineapple tidbits with syrup into 4-side seal sachets. Out of all the contenders, FLtècnics was selected as the optimal choice for this project, offering a complete packaging line that guaranteed the most customer satisfaction.

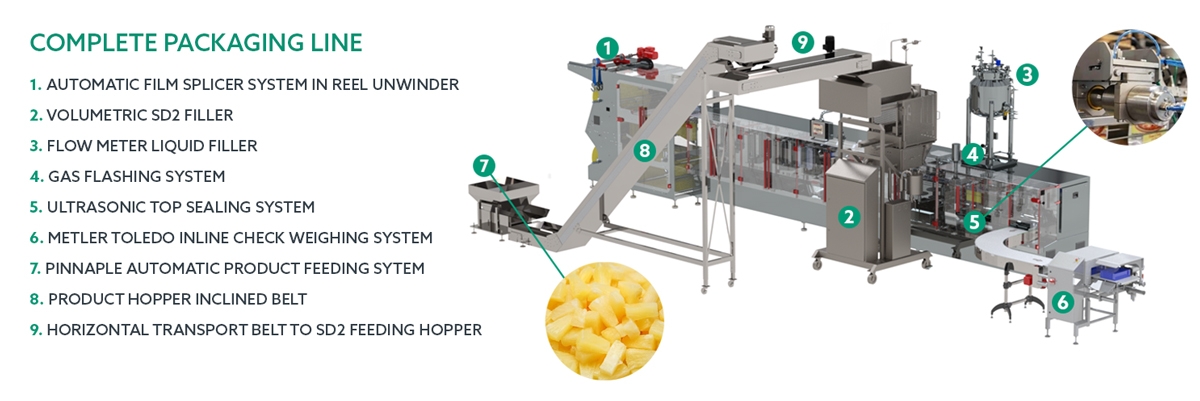

Before adopting FLtècnics' solution, the customer faced several challenges, including low production rates and the need for a significant amount of manual labor to handle the packaging process. FLtècnics' complete packaging line included a Rollstock HFFS machine FL 3.3 H FLT1, an automatic film splicer system, a specially designed volumetric filler for fruit pieces, a gas flashing system, an ultrasonic top sealing system, an in-line checkweigher, and a fully automatic product transport and feeding system.

In the end, thanks to FLtècnics' tailored solution, the customer achieved automated production rates of up to 2,400 sachets per hour. This allowed them to effortlessly package 2.3 kg of delicate pineapple pieces in syrup into top-quality, leak-free 4-side seal sachets, greatly improving their packaging efficiency and product quality.

Customer's Challenges and Requirements

Previous Challenges:

- Manual filling

- Low production rates

- High labor needs

Customer's Requirements:

- Machine reliability

- Efficiency

- Product safety

- Automation

- High production capacity

Packing pineapple tidbits and other delicate fruit products automatically can be a complex task, especially when it comes to meeting the rest of the requirements. That said, FLtècnics took on the challenge and developed the perfect solution to efficiently pack the desired product quantity in premium-quality sachets. This complete packaging line guarantees the highest product integrity throughout the automated packaging process, delivering the quality and consistency all our customers deserve.

FLtècnics' solution

FLtècnics has supplied their customer the following solution: HFFS Rollstock machine model FL 3.3 H FLT1 in simplex version, perfect for packing the product into 4-side seal sachets with production up to 2.400 sachets/hour.

- Product: 2,4 kg of pineapple pieces in liquid syrup

- Speed: up to 40 sachets/minute

- Packaging style: 4-side seal sachet

- Filling system: servo motorized Volumetric SD2 system & Endress & Hausser Mass Flow Meter

Results:

- Customized & Viable solution

- High accuracy dosing < 3%

- Efficiency

- Product’s safety

- Sealing integrity

- Leakage-free finished sachets

Equipment features:

- 3-year warranty on mechanical parts

- 1-year warranty on pneumatical & electrical components

- Integrated automatic film splicing system to work 24/7 shifts uninterrupted

- Servo motorized film feed unit

- Modem connection

- Tear notch sachets for easy opening

- Top & bottom round corners

- Central lubrication system

- Volumetric SD2 filler for tidbits filling

- Mass Flow meter for syrup filling with high accuracy and volume adjustment in real time

- Ultrasonic top sealing to guarantee high pouch hermicity

- Gas flashing system

- Mettler Toledo inline check weighing system

- Fully automatic system of product feeding to SD2 hopper

Key innovations

- Mass flow meter with high accuracy and volume adjustment in real time

- Ultrasonic top sealer to guarantee pouch hermicity

- D2 Servo-motorized fruits filler